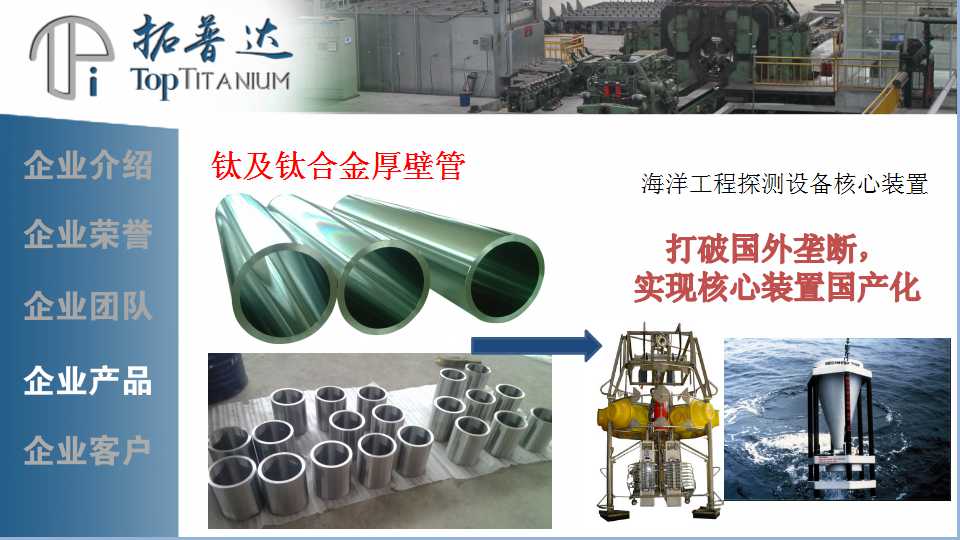

Diameter forged thick wall pip

Intro

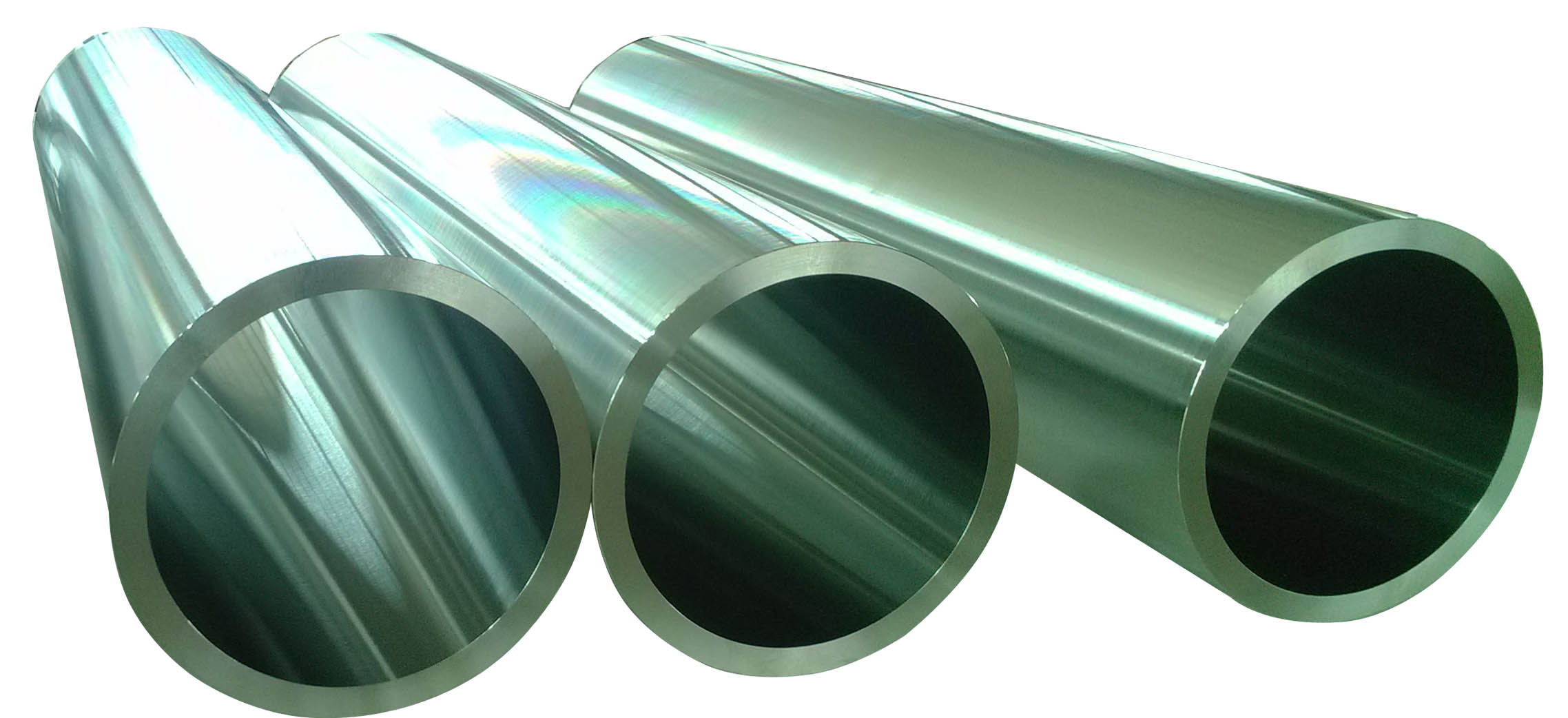

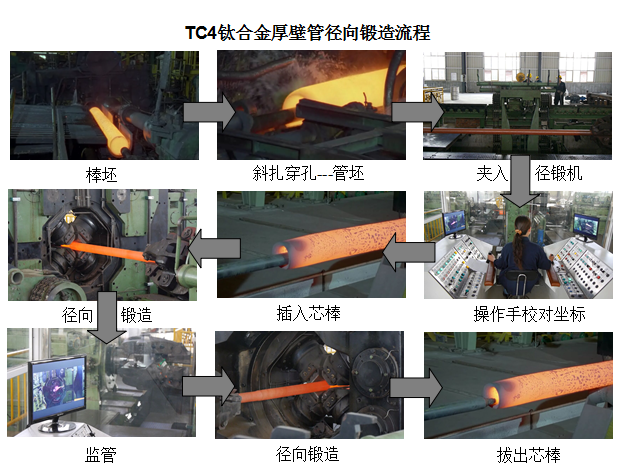

The GFM radial forging machine specializes in the rotary forging of solid or hollow long shaft parts. Forging, the hammers (2-8) distributed in the circumferential direction of the bar are forged and synchronously forged on the workpiece. If the workpiece has a circular cross section, it will rotate at a low speed and move axially. If the workpiece is not cross-section, it will only feed axially without rotating. The feature of radial forging is that no special mold is required. Precision shaft forgings can be forged according to a predetermined procedure. For the forged tube, it is only necessary to follow the given inner diameter size. Set the mandrel size to be directly forged once. Radial forging has a small amount of compression per time, and the number of forgings per minute is high, generally 240-1800/min, which can improve the plasticity of the metal. This method can be used for hot forging or cold forging. The precision of the forging: the outer diameter of the hot forging is 0.5 mm, the inner diameter is 0.1 mm, the outer diameter of the cold forging is 0.1 mm, and the inner diameter is 0.01 mm.

The thick-walled tube is completed by single-pass forging after multiple fires, as shown in Example 2. The single-fire deformation amount is 30-50%, the total forging total deformation is up to 65%, and the total forging ratio is more than 5. At the same time, because it is hollow forged by the core, the forgeability is good, which is more conducive to the uniformity and equiaxification of the pipe structure, and can effectively improve the plasticity value without reducing the strength value.

Example 2: